Four important clearances taken in the piston rings are:

The ring is placed inside the liner and the impression can be taken on a paper by applying Prussian blue paste at the butt ends. The gap between the impressions can then be measured.

- Axial Clearance

- Radial Clearance

- Butt Clearance

- Controlled Pressure Relief groove measurement

Axial Clearance:

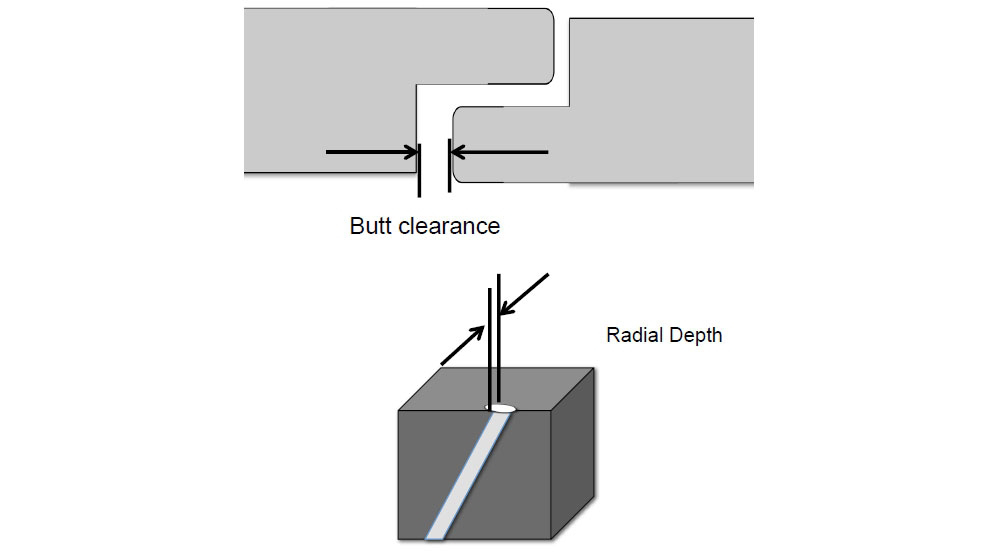

It is the clearance between the ring and the groove to be measured at the top part by a feeler gauge. This clearance is to be measured at four different points for each ring.Radial Clearance:

The radial clearance is the difference between the groove depth and ring width, which can be measured by a vernier caliper

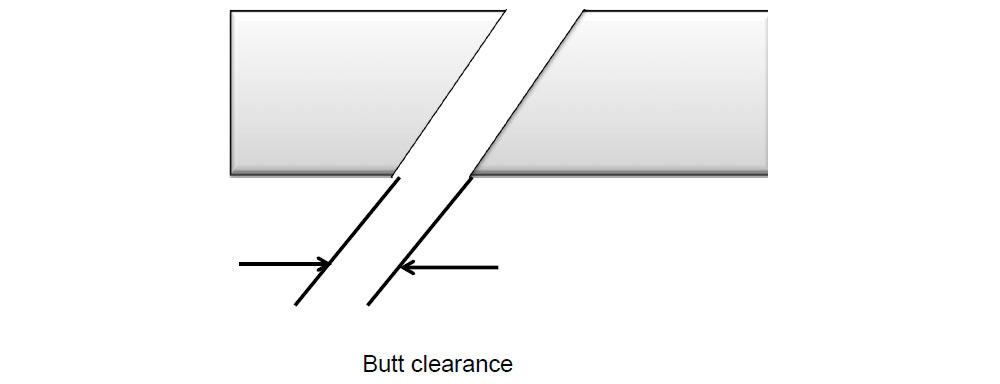

Butt clearance:

It is the clearance between the end butt of the ring inside the liner.The ring is placed inside the liner and the impression can be taken on a paper by applying Prussian blue paste at the butt ends. The gap between the impressions can then be measured.

ReplyDeleteHey what a brilliant post I have come across and believe me I have been searching out for this similar kind of post for past a week and hardly came across this. Thank you very much and will look for more postings from you Best diamond huggie hoops Services Provider

Thanks for sharing the best information and suggestions, it is very nice and very useful to us. I appreciate the work that you have shared in this post. Keep sharing these types of articles here.Celeste Satin Suit Blazer Online

ReplyDeleteThis post is really awesome. Genuinely i like this blog. It gives me more useful information. I hope you share lots of things with us .taparia tools distributors in bangalore

ReplyDeleteSangat bermanfaat... Thanks

ReplyDelete